包阅导读总结

1.

“`

Rolls-Royce、Databricks Mosaic AI、Image Generation、cGAN、Data Intelligence Platform

“`

2.

Rolls-Royce 与 Databricks 合作,利用 Databricks Mosaic AI 工具优化 cGAN 训练过程,带来多方面好处,包括降低成本、提高模型开发速度和准确性等,未来将探索从 2D 到 3D 模型的转变。

3.

– 合作背景

– Rolls-Royce 在多个 AI 项目中见证 Databricks 平台的变革力量

– 项目内容

– 考虑数值、文本和图像数据

– 优化 cGAN 训练过程,增强设计空间探索能力

– 处理多目标约束

– 构建 cGAN 项目的概念架构

– 项目优势

– 降低总拥有成本

– 更快的模型开发时间

– 从实验到部署的无缝过渡

– 提高模型准确性

– 数据管理和治理的益处

– 从模型中获取洞察

– 未来展望

– 探索从 2D 到 3D 模型的转变

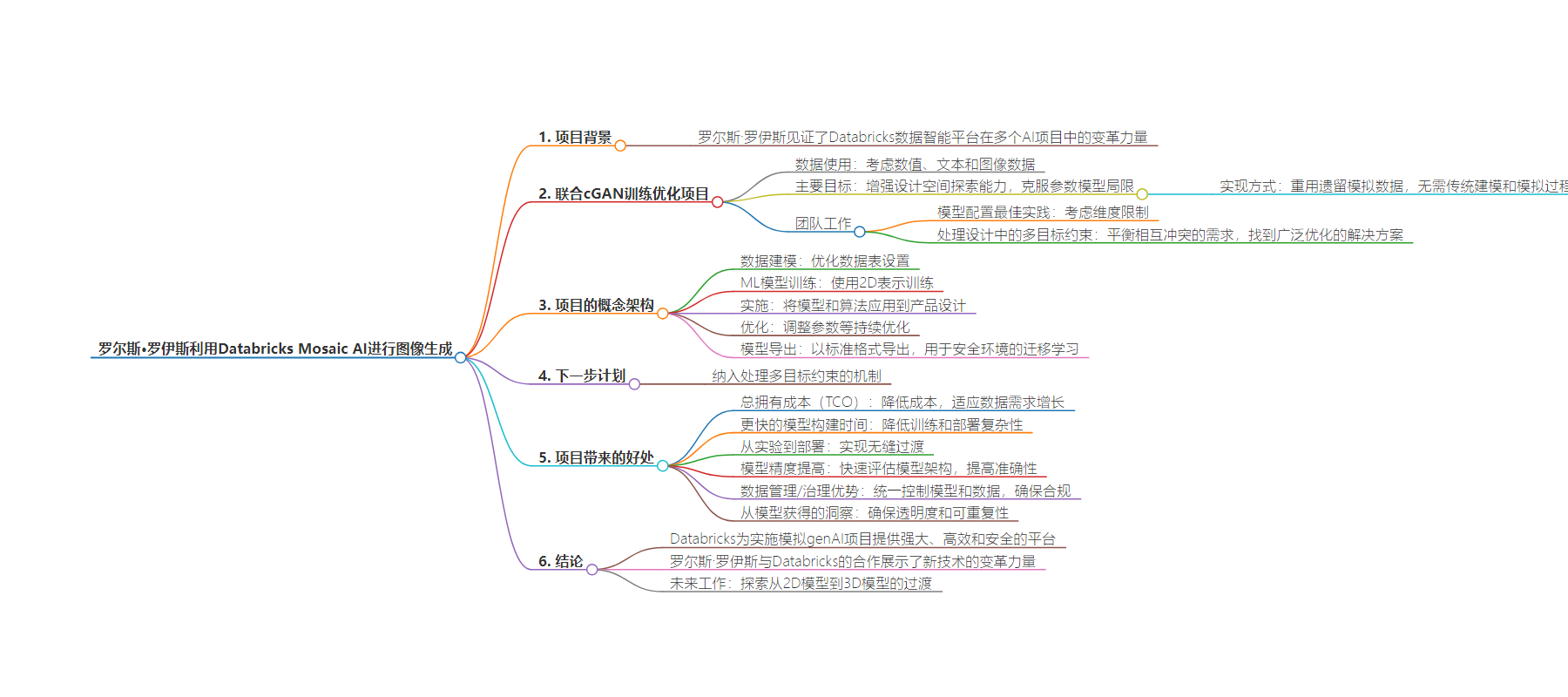

思维导图:

文章地址:https://www.databricks.com/blog/rolls-royce-mosaic-ai

文章来源:databricks.com

作者:Databricks

发布时间:2024/8/8 3:02

语言:英文

总字数:698字

预计阅读时间:3分钟

评分:89分

标签:制造业中的 AI,Databricks 马赛克 AI,条件生成对抗网络 (cGAN),劳斯莱斯,图像生成

以下为原文内容

本内容来源于用户推荐转载,旨在分享知识与观点,如有侵权请联系删除 联系邮箱 media@ilingban.com

Rolls-Royce has witnessed the transformative power of the Databricks Data Intelligence Platform in various AI projects. One example is a collaboration between Rolls-Royce and Databricks, focused on optimizing conditional Generative Adversarial Network (cGAN) training processes, that demonstrate the numerous benefits of using Databricks Mosaic AI tools.

For this joint cGAN training optimization project, the team considered the use of numerical, text and image data. The primary goal was to enhance Rolls-Royce’s design space exploration capabilities and overcome the limitations of parametric models. This was achieved by enabling the reuse of legacy simulation data to drive the identification and assessment of innovative design concepts that satisfy a specified design condition without requiring a traditional geometry modeling and simulation process.

The joint Databricks and Rolls-Royce team investigated best practices for model configuration, including consideration of the dimensionality limits. The approach included embedding knowledge of unsuccessful solutions into the training dataset to help the neural network avoid certain areas and find solutions faster. Another aspect of the project was handling multi-objective constraints in the design process, in this project we were working with multiple requirements that were potentially in conflict: for example, we were trying to reduce the model weight while also trying to increase its efficiency. The goal was to produce a solution that is broadly optimized, not just optimal for a particular facet of the design.

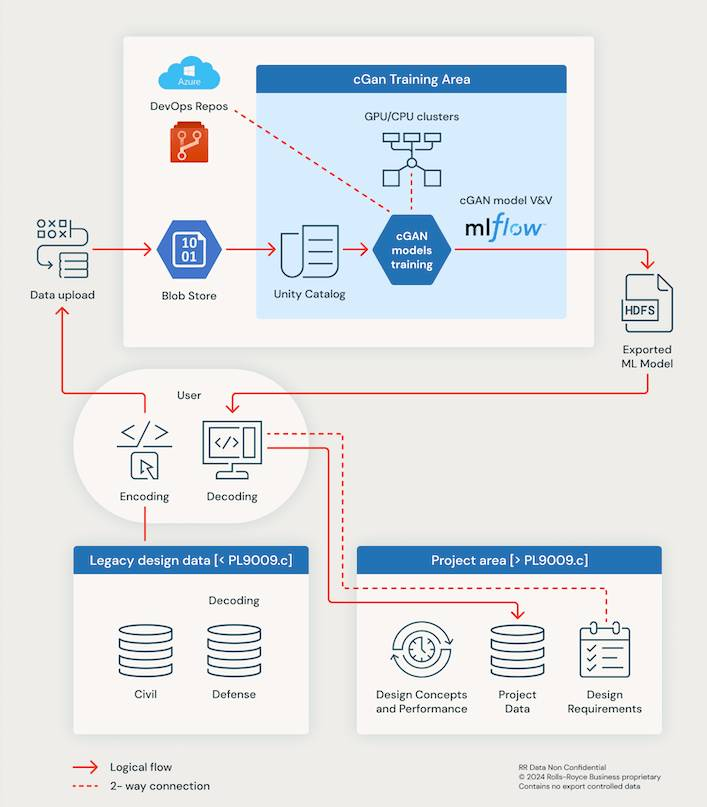

The conceptual architecture for the cGAN project is below.

Description of the conceptual architecture:

- Data Modeling: Data tables are set up to ensure they are optimized for the specific use case. This involves generating identity columns, setting table properties, and managing unique tuples.

- ML Model Training: the developed ML models are trained using a 2D representation of 3D results from typical simulation studies. This involves embedding knowledge of unsuccessful solutions to help the neural network avoid certain areas and find solutions faster.

- Implementation: Once we developed and optimized models and algorithms, we would then implement them into the product design process

- Optimization:Based on current results, we plan to continually optimize the models and algorithms by adjusting parameters, refining the dataset, and ultimately changing the approach to handling multi-objective constraints.

- Model export:The model trained with legacy data can be exported in a standard format, enabling the option of taking a copy to a secure environment where transfer learning can be conducted with project data characterized by a restrictive Export Control or IP classification.

- Next Steps:Moving forward, we plan to include mechanisms to handle Multi-Objective Constraints. We need to handle multiple requirements that can conflict with each other, which requires developing an algorithm or method to balance these conflicting objectives and arrive at an optimal solution.

There were many benefits to Rolls-Royce in leveraging the Databricks Data Intelligence Platform and Databricks Mosaic AI tools for this project:

- Total Cost of Ownership (TCO): Databricks provides a unified lakehouse architecture that accelerates innovation while significantly reducing costs. As data needs grow exponentially, Databricks isa cost-effective solution for data processing. This is particularly beneficial for large-scaleprojects atenterprises like Rolls-Royce.

- Faster Time-to-Model: Databricks Mosaic AI tools reduce modeltraining and deployment complexity, enabling faster time-to-model. This is achieved through features such asAutoML and Managed MLflowwhich automate ML development and manage the full lifecycle of ML models.

- From Experimentation to Deployment: Databricks provides a seamless transition from experimentation to deployment. This is crucial as moving from experiments to production deployments can be challenging.

- Improvement of Model Accuracy: Databricks enables a rapid assessment of model architectures throughprovisioning access to bespoke packages such as Ray, simplifying the execution of hyperparameter studies, and enabling both scalability (through the execution of more complex use cases that would not be viable through standards machines) and concurrent development (multiple individuals working on or having access to the model). This not only speeds up the model development/testing process but also improvesaccuracy.

- Data Management / Governance Benefits: The Databricks Data Intelligence Platform provides complete control over both the models and the data. This level of control is crucial for compliance-centric industries like aerospace. The implementation of Unity Catalog establishes a crucial governance framework, providing a unified view of all data assets and making it easier to manage and control access to sensitive data.

- Insights Gained from the Models: The integration of MLflow in Databricks ensures transparency and reproducibility, key factors in any AI project. It allows for efficient experiment tracking, results sharing, and collaborative model tuning. These insights are invaluable in driving business innovation and enhancing productivity.

In conclusion, Databricks provides a robust, efficient, and secure platform for implementing simulation genAI projects. The collaboration between Rolls-Royce and Databricks has demonstrated the transformative power of this new technology. Given the three-dimensional nature of engines, future work will include exploring the transition from 2D models to 3D models.